Brussels (Belgium) / Melle (Germany), 6 April 2017 - ZetesMedea Voice picking enabled Assmann Büromöbel to increase productivity by 20% and reduce the error rate to 0%. Increased execution efficiency streamlined stock management and enables integration of temporary workers. ROI was achieved in less than 24 months.

The picking of furniture parts is crucial for Assmann Büromöbel. Every day, two shifts of up to seven pickers pick around 4 500 individual parts, which are then assembled into desks, storage space concepts, docking* and partition** systems or reception furniture. On average, a piece of office furniture at Assmann consists of ten parts, including doors, side panels etc.

The picking process of the wooden furniture parts was prone to picking errors and costly delays in the assembly and incorrect stock inventories. Another problem was the steep learning curve for the 15 colleagues who regularly work as temporary order pickers.

Assmann looked for a new order picking system that would guide even new employees quickly and faultlessly through the order picking process. The primary objective for Assmann was to increase efficiencies and performance. "It was clear to us that voice picking was best suited to meet this goal," explains Uwe Bahr, Information Technology and Organisation Development Manager at Assmann Büromöbel.

Operator independent

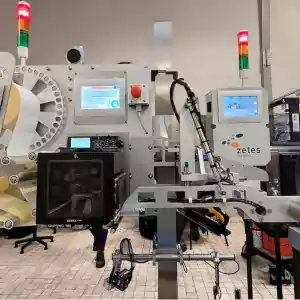

After an analysis of various providers, a decision was made in favour of the ZetesMedea Voice solution, powered by MCL™ Voice. "From the start, we felt reassured by the competence and expertise of Zetes," says König-Slickers, who was responsible for the introduction of Pick by Voice as the project manager.

"ZetesMedea Voice is a rapid deployment solution which is intuitive to use and independent of operator specific set up. There is no need for creating an individual voice profile for each picker, which reduces the training period", says König-Slickers. Another advantage of the solution was the easy integration with Assman’s manufacturing management system ‘Profile Systems’. On top of the software, Assmann invested in 7 Zebra W41 terminals and 15 headsets.

Zetes reviewed and optimised the core business process: increase efficiency and reduce inventory levels. By streamlining and aligning, the picking and assembly processes enabled Assmann to prepare orders on the date of the assembly, increasing throughput performance of each order which allowed reducing the stock considerably.

0 errors and 20% performance increase

Operators have their eyes and hand free during the voice picking process. “Our picking performance has increased by around 20 percent from a previous 120 picks per hour to 143 picks per hour now. At the same time, the error rate has been lowered to 0 percent. Thanks to the real-time control, picking the wrong furniture parts is practically impossible”, says Uwe Bahr.

Since April 2014 ZetesMedea Voice has proven its worth day after day. It has generated a return on investment in less than two years. As a next step, Assmann Büromöbel wants to implement the ZetesMedea Voice solution in the picking process of small parts such as hinges and handles, which are now picked by the assembler while manufacturing. "Pick by Voice is an integral component of manufacturing in our plant and meets our aim for continuous improvement," plans Bahr.

*All necessary power and data connections are space-saving and ergonomically integrated into the office furniture. Assmann has a patent for this solution and has been awarded with the Reddot.

**Screens, as used in large offices or call centres to dampen the sound.

- END -

About Assmann Büromöbel GmbH & Co. KG

Assmann Büromöbel GmbH & Co. KG is a traditional, medium-sized family business the roots of which go back to 1939. At the company headquarters in Melle, Assmann develops and produces high quality desks, storage space concepts, docking and partition wall systems, as well as reception furniture. The service goes from individual consultation on professional room planning to supply with own trucks and assembly on site.

The owner-operated manufacturer already in its third generation is represented in Germany, Great Britain, Switzerland and the Netherlands. A network of over 100 specialist trading partners in Germany and sales partners in France, Belgium, Luxembourg, Poland, Austria, Hungary, Italy, Romania and Russia have provided increasing turnovers in the most important European markets for many years. Every day, around 2 000 items of furniture are produced in Melle. In 2015, Assmann Büromöbel achieved the Oskar Patzelt Foundation's first prize for traditional medium-sized companies. At the same time, the Assmann Office Furniture Applica Docking System was awarded the Red Dot Design Award.

For further information visit www.assmann.de.

“Our picking performance has increased by 20 percent to 143 picks per hour. At the same time, the error quota is lowered to 0 percent."

Uwe Bahr, Information Technology & Organisation Development Manager, Assmann Büromöbel