Eindhoven (the Netherlands), 3 February 2026 – 247TailorSteel, a leading manufacturer of custom metal parts, enhances delivery visibility with ZetesChronos Proof of Delivery solution. The software enables seamless, paperless documentation of delivered orders by linking drivers with the metal processing company's back office. The key advantage lies in providing 247TailorSteel and its customers with real-time delivery traceability. Time savings in the shipping department enabled 247TailorSteel to recover its investment in the solution within 6 months.

Consignment note digitalisation

Consignment note digitalisation

With rapid growth, 247TailorSteel sets itself apart through highly automated and optimised processes across its operations. Customer deliveries are managed from six branches across the Netherlands, Belgium, and Germany, using a fleet of around thirty in-house drivers and select external carriers. “Until the start of this year, we were still using paper consignment notes in shipping”, says Leon Stolk, logistics planner at 247TailorSteel. “That final step has now been digitised with the ZetesChronos Proof of Delivery (ePOD) software.”

Fast return on investment

“The key factors in selecting Zetes were the adaptable, scalable features of ZetesChronos and their strong position in ePOD”, continues Stolk. “Given our business case, the decision to invest was straightforward; we recouped the cost of the software and PDAs through time savings in shipping in under six months. I have seen very few IT projects reach ROI this swiftly. With electronic proof of delivery, our costs per delivery have been reduced by a factor of four compared to paper consignment notes. Also, the ease of use and practical advantages experienced by our drivers daily have led to high acceptance.”

“The transparency we now offer through real-time traceability means we get fewer phone calls and emails, which also saves time and increases customer satisfaction” says Stolk

Real-time insight and traceability

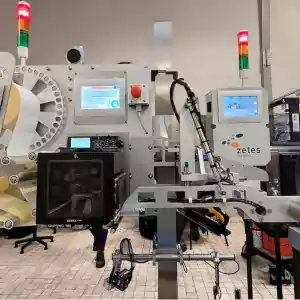

Currently, around thirty drivers across all 247TailorSteel branches use ZetesChronos on Datalogic Memor 35X PDAs. Another key benefit is the real-time traceability of all lorries en route to customers. From the head office in Varsseveld alone, some 250 pallets of various sizes are sent to customers daily.

Return packaging and pick-up counter

247TailorSteel will soon implement ZetesChronos software to document return packaging and digitise consignment notes at pick-up counters. “For the return packaging, we are then able to capture both a digital signature and a supporting photo”, adds Stolk. “We also aim to integrate track & trace data for customer deliveries into our cloud-based ordering platform. This approach is helping us build an increasingly comprehensive and intelligent self-service system for our customers.”

Joint implementation of ePOD

The company maintains a large in-house IT department of around 50 employees who develop most of the company’s applications to optimise all processes in line with internal needs. The ePOD solution was both provided and jointly implemented by Zetes. “We established a strong rapport with the Zetes team early on, and it’s continued to develop positively”, concludes Stolk. “Throughout the implementation, they collaborated closely with us to ensure a successful rollout and brought real value through their expertise.”

- END -

About 247TailorSteel

247TailorSteel has over 15 years of experience in the metal processing industry, employing nearly 1,000 people across six branches in the Netherlands, Belgium, and Germany. The company supplies custom-sized laser-cut sheet and tube materials. Thousands of customers rely on the Sophia online platform to order custom-cut metal sheets, tubes, and folded components.