Tobacco Serialisation

Tobacco serialisation gives you full product traceability and visibility

For your business to manage the flow of products, meet market challenges and comply with legalisation, it’s vital you can easily identify the goods you are handling. ZetesAtlas is an identification and serialisation solution that helps you track and trace products throughout your supply chain using product serialisation, multi-level aggregation and e-pedigree registration.

Find out more Contact usThe benefits of tobacco serialisation

Comply with legislation

Meet current and future regulations and legislation.

Visibility and Traceability

Make sure fulfilment is controlled inbound and outbound..

Protect consumer safety

Be sure of product authenticity and manage recalls.

Reduce costs

Reduce stock levels, guarantee uptime and fight grey market.

Personalise communication

Enable customised communication and marketing.

A secure integration

ZetesAtlas manages and controls all your tobacco serialisation and aggregation processes. You will have Operational Equipment Efficiency (OEE) and total productivity of your packaging lines. The system integrates with your ERP, MES, PES and Track & Trace repository and can securely generate unique serial numbers or pull them from an external source.

The key features of our tobacco serialisation system

- Ensures Operational Equipment Efficiency (OEE).

- Provides efficient and centralised line management.

- The technology works independently.

- Creates a serialisation audit trail.

- Generates serial numbers or allocates them from an external source.

- Provides validation with a control, check and verify process.

- Establishes e-Pedigree.

Request a free, non-binding consultancy meeting

If you would like a no obligation discussion regarding the directive and how to ensure readiness for your business then please don’t hesitate to get in touch with us. And discover the benefits of having a primary repository & business solution under one roof.

A modular, scalable solution

The need for serialized product tracking may differ from one company to another.

That’s why we will always begin by evaluating your existing processes. We work with your teams to look at your requirements and then agree the appropriate level of serialisation, aggregation and de-aggregation needed. You can start small and add additional functionality later on.

Download your free copy of the Zetes’ Tobacco Serialisation Guide

In this quick and easy guide, learn about the top considerations for tobacco manufacturers and importers including:

- What are the major operational impacts?

- How to start preparing forcompliance?

- What are the important steps to take towards compliance?

- How to future-proof your serialisation and aggregation implementation?

- What to look for in a specialised partner to guide through implementation?

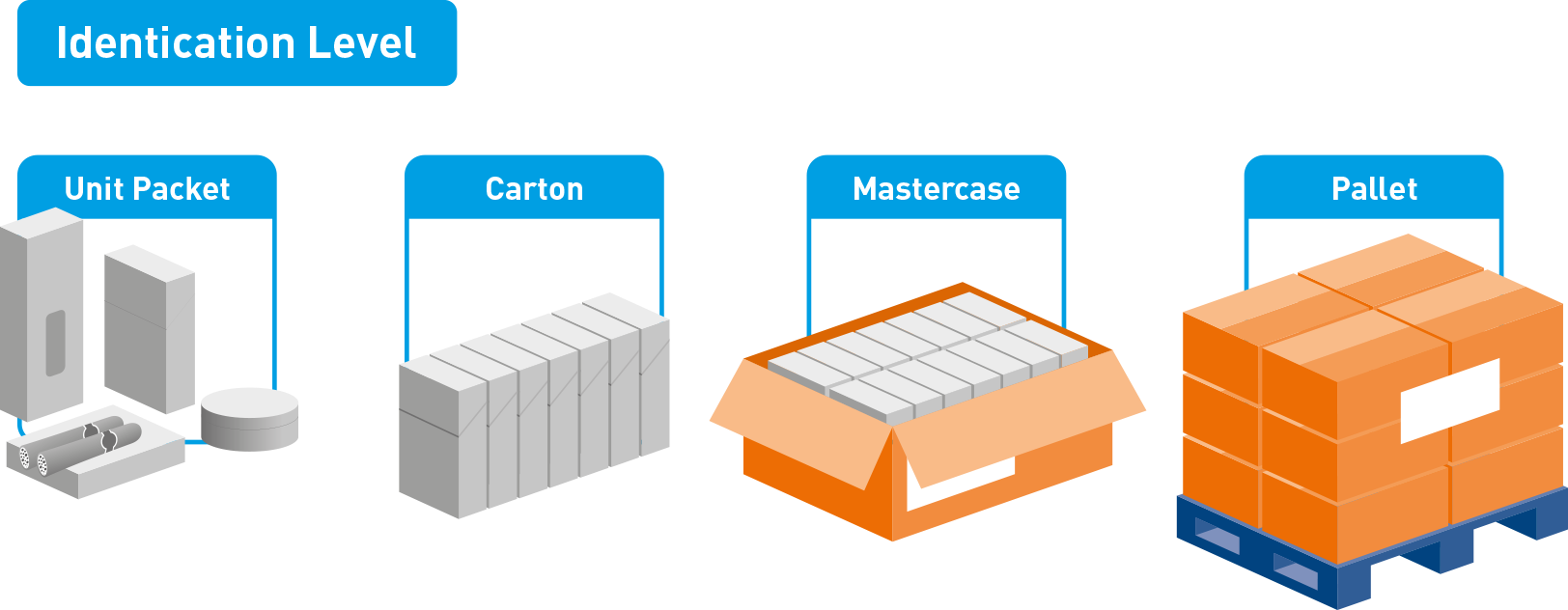

Industrial coding and marking

Our tobacco serialisation software manages serialisation at any logistical level including item carton, bundle, box, and pallet. It can be used on existing packaging lines or run on one of our industrial labelling systems and marking systems. All machines are designed and manufactured in-house to give you maximum uptime on your packaging line.

Who benefits from tobacco serialisation?

Our serialisation specialists work with companies in a variety of industries:

Vape Manufacturers:

Tracking of components to check uptime and control quality.

Cigar Manufacturers:

Track and trace of luxury goods from raw materials to finished products in stores. This ensures authentication and controls the distribution channel.

Cigarello Manufacturers:

Providing end-to-end unit traceability of the whole manufacturing chain

Any other tobacco related manufacturers:

Unit level serialisation to comply with the Tobacco Products Directive

Contact our specialists to find out more about these projects or check out our reference section

A foundation for full supply chain visibility

Tobacco serialisation allows you to build the parent-child relationships as goods move through the supply chain.

At each packaging stage information is collected, parent codes are assigned and data is recorded. By capturing relevant data and sharing them with relevant stakeholders within your connected supply chain, you will be able to:

- Reduce risk as you will be able to react instantly

- Control product provenance from internal and external suppliers

- Protect your supply chain from production through to point of sale

- Control distribution channels by fighting parallel and grey markets

- Manage product recalls efficiently

Who do we help?

“Thanks to ZetesAtlas, we now have a complete overview on all the logistics activities throughout our tobacco supply chain.”

Cédric Santelé, CEO, CTS

Why work with Zetes?

- We have over 30 years of experience in packaging identification execution.

- Our in-house software and hardware development is driven by an in-depth understanding of complex, global traceability processes in demanding markets.

- Having a single point of contact removes risk and complexity.

- Our Datamatrix marking and serialisation solutions are running at leading pharmaceutical manufacturers.

- Having over 30 offices across Europe allows us to help you as and when you need it.